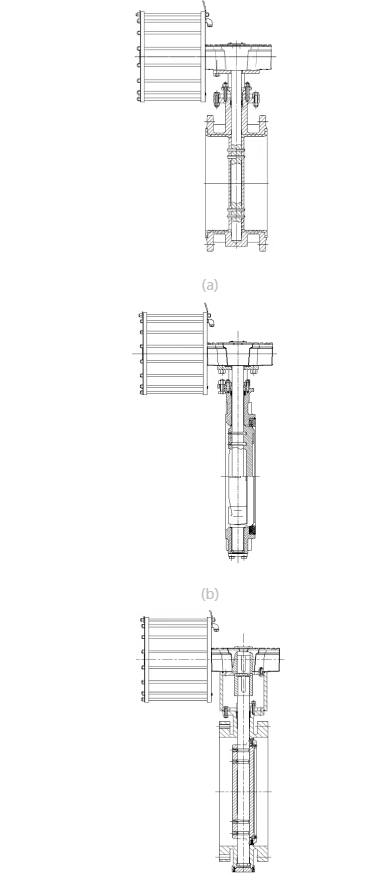

Structural classification of seawater butterfly valves. Currently, most purchasers and owners mainly choose three types of seawater butterfly valves: center line soft seal rubber lined butterfly valve, double eccentric soft seal high performance butterfly valve, triple eccentric hard seal butterfly valve. The structural diagrams of the three types of seawater butterfly valves are shown in the figure.

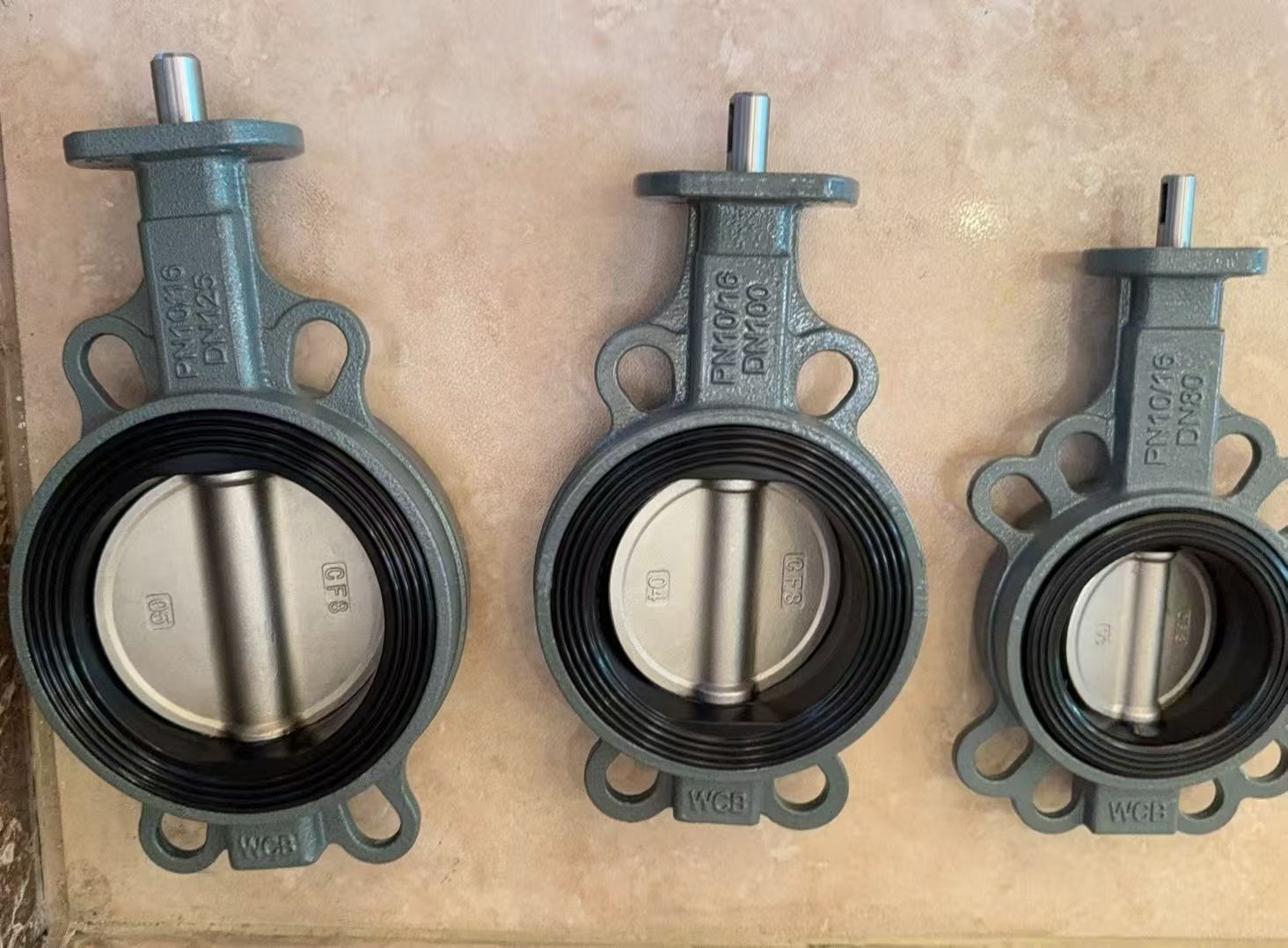

Valve Material Analysis: Seawater's corrosive effects on valves primarily include electrochemical corrosion and high-concentration salt ion corrosion. Electrochemical corrosion is caused by the strong electrical conductivity of seawater. Contact between dissimilar metals and seawater can lead to galvanic corrosion, accelerating metal corrosion. High-concentration salt ion corrosion occurs when metals react with chloride and sulfate ions in seawater, damaging the protective layer on the metal surface, leading to corrosion and reducing material durability. The centerline rubber-lined soft-seal butterfly valve isolates the valve body from seawater through a rubber lining. The rubber lining is made of EPDM, which is highly resistant to seawater corrosion. EPDM rubber is highly resistant to corrosive media such as acids, alkalis, and salts, making it widely used in saline marine environments. This material is not only resistant to seawater but also to various chemicals found in seawater, such as sulfates and sodium ions. Because the rubber lining isolates the valve body from seawater, carbon steel can be used for the valve body. Specific component material selections can be found in the table.

Valve Material Analysis: Seawater's corrosive effects on valves primarily include electrochemical corrosion and high-concentration salt ion corrosion. Electrochemical corrosion is caused by the strong electrical conductivity of seawater. Contact between dissimilar metals and seawater can lead to galvanic corrosion, accelerating metal corrosion. High-concentration salt ion corrosion occurs when metals react with chloride and sulfate ions in seawater, damaging the protective layer on the metal surface, leading to corrosion and reducing material durability. The centerline rubber-lined soft-seal butterfly valve isolates the valve body from seawater through a rubber lining. The rubber lining is made of EPDM, which is highly resistant to seawater corrosion. EPDM rubber is highly resistant to corrosive media such as acids, alkalis, and salts, making it widely used in saline marine environments. This material is not only resistant to seawater but also to various chemicals found in seawater, such as sulfates and sodium ions. Because the rubber lining isolates the valve body from seawater, carbon steel can be used for the valve body. Specific component material selections can be found in the table.

Centerline Butterfly Valve Materials

| Part Name | Body | Seat | Disc | Stem |

| Material | WCB/QT450 | EPDM | C95800/4A | Monel 400 |

Since the valve body of the double eccentric soft-seal high-performance butterfly valve is in direct contact with the medium, the valve body material is generally selected to be duplex stainless steel that is resistant to seawater corrosion, and the butterfly plate and valve stem are also made of duplex stainless steel. The duplex phase of duplex stainless steel refers to the ferrite phase and the austenite phase. This material has the characteristics of both austenite and ferrite. Compared with ferrite, it has better toughness and plasticity, no room temperature brittleness, and significantly improved welding performance and intergranular corrosion resistance. It has the characteristics of 475 ℃ brittleness of ferritic stainless steel, high thermal conductivity, and superplasticity; compared with austenitic stainless steel, its strength, resistance to chloride stress corrosion, and resistance to intergranular corrosion are significantly improved. The microstructure of duplex stainless steel contains high levels of chromium and molybdenum elements, which can form a dense oxide film to prevent the intrusion of corrosive media. In seawater environments, duplex steel exhibits good resistance to pitting and crevice corrosion, and can effectively resist seawater corrosion and wave impact in marine engineering. See the table for material selection for double eccentric soft-seal high-performance butterfly valves.

Double eccentric butterfly valve material table

| Part Name | Body | Seat | Disc | Stem |

| Material | 4A/5A | RPTFE | 4A/5A

| F53 |

The hard-sealed triple eccentric butterfly valve is the same as the soft-sealed double eccentric high-performance butterfly valve. The valve body is also in direct contact with the seawater medium. The difference is that due to structural reasons, the butterfly plate sealing ring material adopts a multi-layer structure of duplex steel + PTFE or a pure hard sealing structure of duplex steel welded Stellite. The material selection of the triple eccentric hard-sealed butterfly valve is shown in the table.

Triple eccentric butterfly valve material table

| Part Name | Body,Disc | Seat | Butterfly Disc Seal | Stem |

| Material | 4A/5A | Surfacing STL | 2205+PTFE/2205+STL

| F53 |

Valve Sealing Performance Analysis: The centerline rubber-lined soft-seal butterfly valve features a centerline structure, with its axis aligned with the pipeline axis and its center of rotation located at the center of the pipeline. This design ensures well-balanced torque during opening and closing, smoother operation, and a simple structure. Its soft seal design offers excellent sealing performance and enables bidirectional sealing. However, since the centerline butterfly valve seal relies on elastic deformation caused by the rotation of the butterfly disc squeezing the valve seat, pipeline media pressures must be limited. It is only suitable for media pressures ≤ 1.6 MPa. For diameters exceeding DN600, media pressures must not exceed 1.0 MPa. Improving sealing performance by squeezing the valve seat ring significantly increases valve torque, and the seat ring and butterfly disc experience partial squeezing and scraping in all opening and closing positions, leading to rapid wear. Therefore, centerline rubber-lined butterfly valves are not recommended for media pressures exceeding 1.0 MPa. Double-eccentric soft-seal high-performance butterfly valves employ a double-eccentric structure, with the stem rotation center offset from the center of the disc seal ring cross section, and offset from the center of the valve body flow path. The double eccentric valve can quickly separate the butterfly disc from the valve seat at the moment of opening, and there is no continuous squeezing and scraping between the butterfly disc and the valve seat. In addition, the double eccentric soft-seal high-performance butterfly valve improves the valve seat structure based on the traditional double eccentric butterfly valve: the valve seat sealing ring is designed as a structure with a U-shaped groove, the butterfly plate is an integral structure, the butterfly plate sealing surface is welded with Stellite, and finally ground and polished. This structure has the following advantages: (1) Due to the special structure of the valve seat, the double eccentric soft-seal high-performance butterfly valve can achieve the bidirectional full pressure differential sealing requirement and is suitable for seawater medium working conditions with a pressure of ≥1.6 MPa. The valve seat structure is shown in Figure 2. Its sealing principle is: when the pressure is applied from the direction of the valve seat sealing ring, the medium pressure is squeezed on the U-shaped groove of the valve seat sealing ring, so that the valve seat sealing ring is close to the butterfly plate. The greater the pressure, the better the valve sealing effect; when the pressure is applied from the direction of the valve stem, the butterfly plate is pushed close to the valve seat sealing ring, and the valve seat pressure ring presses the valve seat sealing ring tightly, so that the valve seat sealing ring is close to the butterfly plate, thereby achieving a sealing effect.

(2) The valve seat seal is a movable seal. When the valve seat seal is damaged, it is easy to repair and disassemble. If there is a fire protection requirement, a metal fireproof ring can be installed at the valve seat seal. When a fire occurs and the valve seat seal is burned, the metal fireproof ring and the butterfly plate can form a sealing pair. (3) The opening and closing torque of the switch is small, and the wear between the butterfly plate and the valve seat seal is small during switching. It is suitable for high-frequency operation and has a long service life of more than 1 million times. However, this structure has high requirements for the dimensional tolerance and processing accuracy of the butterfly plate and the valve seat seal, and the valve sealing effect depends on the closed position, and has strict requirements for the closed position. Therefore, when the medium pressure is greater than 1.0 MPa, the sealing requirements are relatively strict, and bidirectional isobaric sealing is required, the double eccentric soft seal high-performance butterfly valve is the preferred choice. The three eccentricities of a triple-eccentric butterfly valve are the dimensional eccentricity a between the valve stem rotation center and the center of the disc seal cross section; the dimensional eccentricity b between the valve stem rotation center and the valve body flow path center; and the angular eccentricity c between the valve body center and the angular center of the valve body sealing surface.

When a triple-eccentric butterfly valve is fully open, the disc seal is completely separated from the seat sealing surface, leaving a gap between them. Only during closing does the disc seal press against the seat sealing surface. Due to the eccentricity angle c, the tangents of the disc seal's rotational trajectory on the large and small semicircles of the disc's rotation form angles α1 and α2 with the seat sealing surface (see Figure 4). This allows the disc seal to gradually separate and press against the seat sealing surface during valve opening and closing, eliminating mechanical wear and abrasion between the two during valve opening and closing. Thanks to the presence of α1 and α2, the pressure ratio between the sealing pairs of a triple-eccentric butterfly valve can be varied by adjusting the actuator's output torque, thereby adjusting the pressure ratio on the sealing surfaces. Based on the above structural characteristics, triple-eccentric butterfly valves offer excellent sealing performance, long service life, and no strict requirements for the closed position. They maintain excellent sealing performance even under high pressure or solid particle conditions, reducing the risk of leakage. However, the disadvantage of triple-eccentric sealed butterfly valves is their high processing cost. Under the same conditions, their bidirectional sealing effect is inferior to that of double-eccentric soft-seal high-performance butterfly valves. Therefore, when the medium pressure is greater than 1.0 MPa and there is no requirement for bidirectional isobaric sealing, triple-eccentric hard-seal butterfly valves can be selected.

Economic Analysis: Because the rubber lining of the centerline butterfly valve body doesn't come into contact with seawater, the valve body can be made of inexpensive carbon steel. The valve also has fewer components, making processing simple and reducing overall procurement costs. However, if the seat seal is damaged, repairs require the entire valve to be removed from the pipeline and returned to the valve manufacturer for re-lining, resulting in high repair costs. The double-eccentric, soft-seal, high-performance butterfly valve body comes into direct contact with seawater, so the valve body is made of more expensive duplex stainless steel. Similarly, the valve body also has fewer components. The double-eccentric, soft-seal, high-performance butterfly valve seat is replaceable. If the valve leaks due to damage to the seat sealing surface, the seat can be replaced directly on-site, making repairs easy and cost-effective. However, this structure places strict processing requirements on the valve body, butterfly plate, and valve seat, resulting in complex and costly processing. The overall price is higher than that of the centerline butterfly valve. The triple-eccentric hard-sealed butterfly valve is the same as the double-eccentric soft-sealed high-performance butterfly valve. The valve body is in direct contact with seawater, so the valve body material is also made of more expensive duplex stainless steel; however, it has more parts, complex processing and high processing costs, and the overall price is between the centerline butterfly valve and the double-eccentric soft-sealed high-performance butterfly valve.

This paper takes three common seawater butterfly valves as the analysis object, and elaborates on them from three aspects: material selection, valve sealing performance, and economy. The main conclusions are as follows: (1) When the medium pressure is less than 1.0 MPa, choose a centerline rubber-lined butterfly valve; (2) When the medium pressure is greater than 1.0 MPa and there is no requirement for bidirectional isobaric sealing or the medium contains a lot of impurities, choose a triple-eccentric hard-sealed butterfly valve; (3) When the medium pressure is greater than 1.0 MPa and there is a requirement for isobaric bidirectional sealing, choose a double-eccentric high-performance soft-sealed butterfly valve. Accurately selecting a seawater butterfly valve that meets the project requirements and pipeline process parameters can not only ensure the normal operation of the entire project, but also save the procurement and maintenance costs of the entire project.