-

Mobile Version

Scan with Mobile

- Member Center

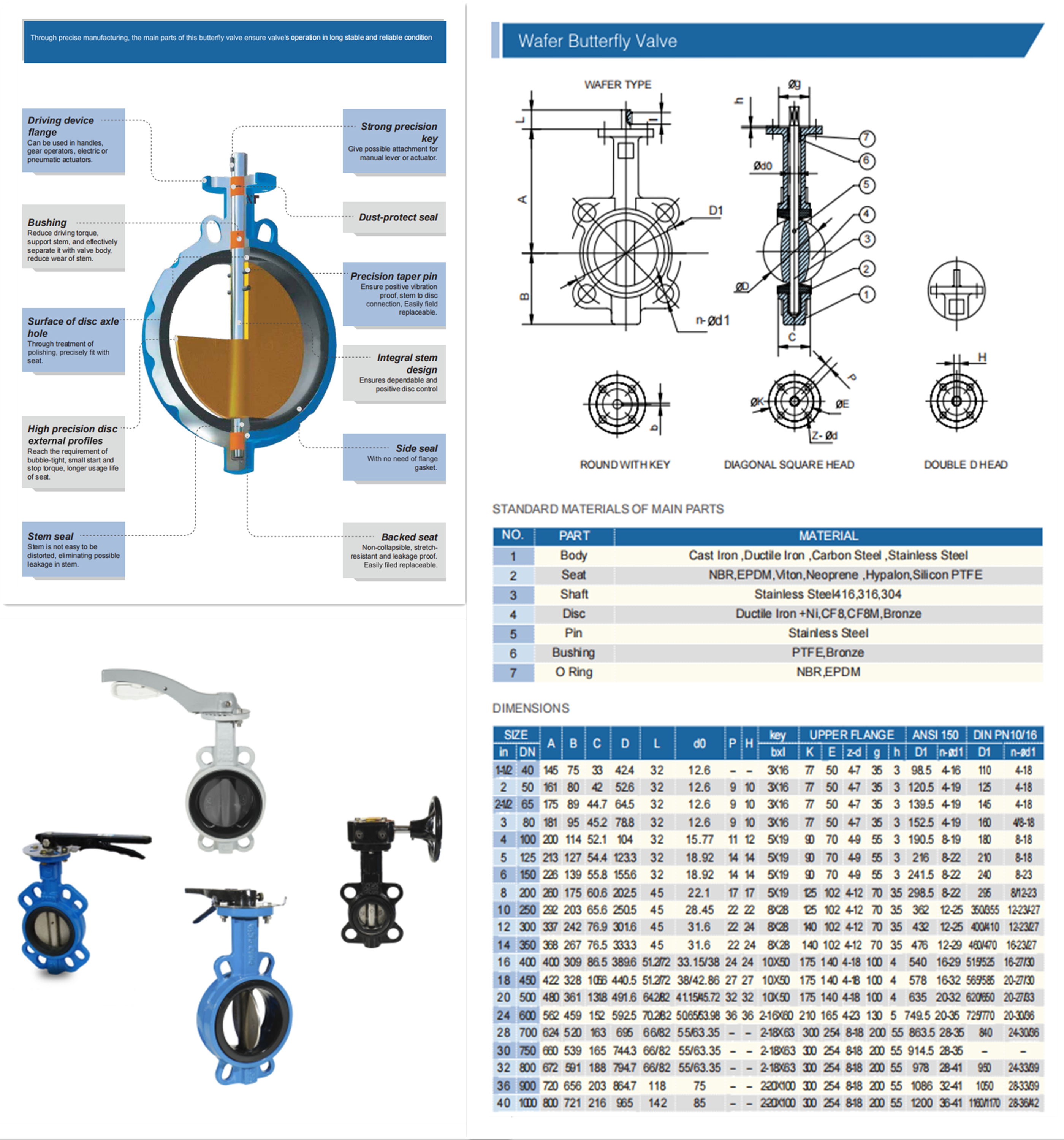

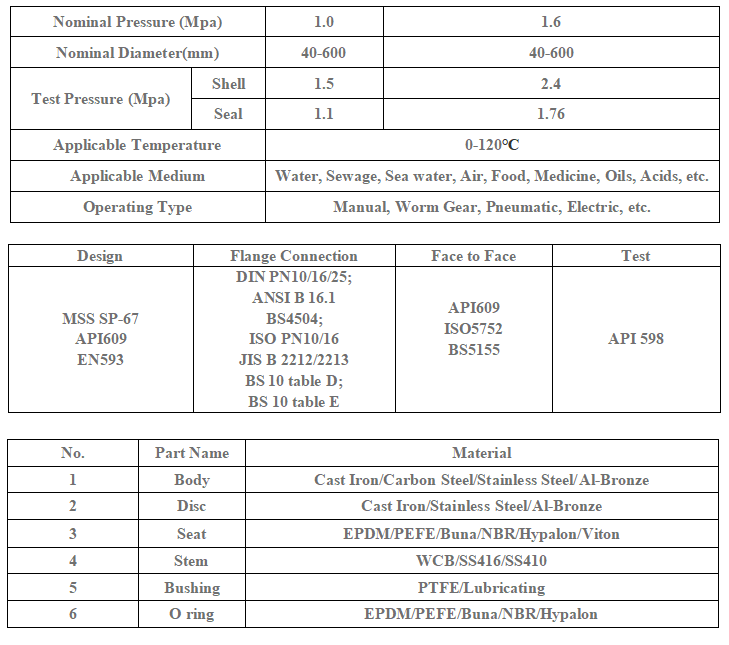

Specifications:

Size: DN50-DN1200

Pressure: PN10/16, Class150,JIS6K/10K

------------------------------------------------------------------------------------------

Materials:

Body :Ductile Iron

Disc: SS316

Seal : PTFE

Stem : SS416

-----------------------------------------------------------------------------------------------------------------

Operated:Pneumatic Type-Pneumatic Type With Pneumatic Triplex

Applicable medium:Water, Oil, Gas

Date Sheet :

The pneumatic valve triplex, also known as the air source processing triplex, consists of an air filter, a pressure reducing valve and an oil mist collector.

These components play a vital role in the pneumatic system:

1. Air filter: Its main function is to filter out impurities, moisture and solid particles in the compressed air to protect the subsequent pneumatic equipment from contamination. Through filter elements such as filter elements or filter screens, impurities in the air can be effectively removed to improve the stability and life of the system.

2. Pressure reducing valve: The pressure reducing valve is used to adjust the pressure of the gas and adjust the high-pressure gas source to the required low-pressure output. It controls the pressure of the medium by adjusting the pressure regulating diaphragm or spring and maintains the stability of the output pressure. The pressure reducing valve can ensure that the air pressure in the pneumatic system is within a certain range to meet the working requirements of the pneumatic actuator.

3. Oil mist collector: The oil mist collector is mainly used to provide lubricating oil mist for the pneumatic system to reduce the friction and wear of the pneumatic equipment. It plays a lubricating and protective role by mixing the lubricating oil mist with the compressed air and transporting the oil mist to the pneumatic equipment that needs lubrication through the airflow.

In summary, the pneumatic valve triplex ensures the stable operation of the pneumatic system and extends the service life of the equipment through the functions of filtering, pressure reduction and lubrication.