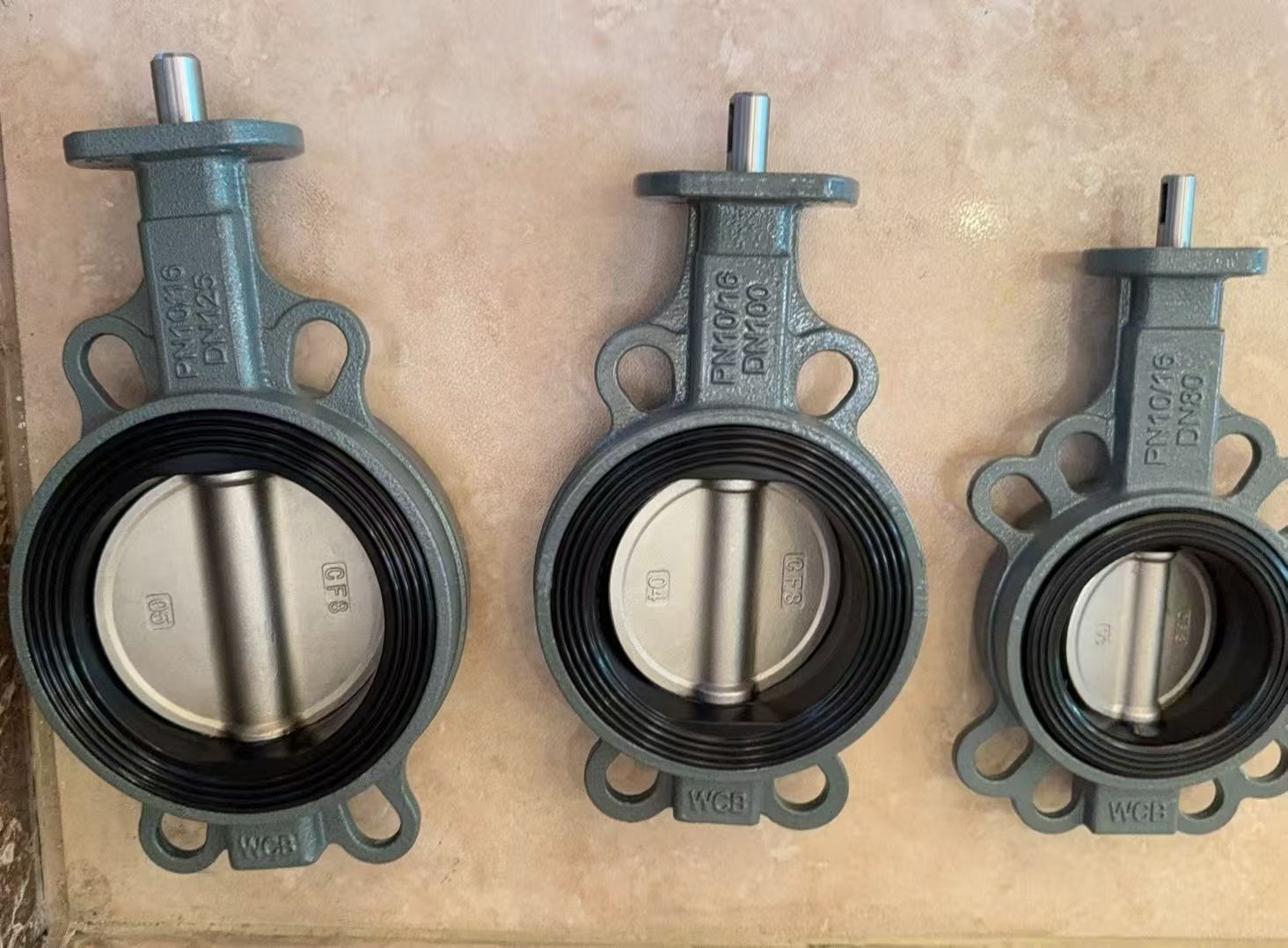

The quality of the sealing surface as the core component of the valve directly affects the service life of the valve.

When selecting the sealing surface material, its corrosion resistance, abrasion resistance, erosion resistance and oxidation resistance must be considered.

The following is a classification of commonly used sealing surface materials:

Soft materials:

1.Rubber: including nitrile rubber and fluororubber, with excellent corrosion resistance and elasticity.

2.Plastics: such as polytetrafluoroethylene and nylon, with strong corrosion resistance and suitable for a variety of chemical media.

Hard sealing materials:

1.Copper alloy: suitable for low-pressure valves, affordable, but average wear resistance.

2.Chromium stainless steel: used for ordinary high and medium pressure valves, with high hardness and good wear resistance.

3.Stellite alloy: specially designed for high-temperature and high-pressure valves and highly corrosive environments, with excellent corrosion resistance and high-temperature strength.

4.Nickel-based alloy: especially suitable for corrosive media such as nitric acid and acetic acid, with strong durability.