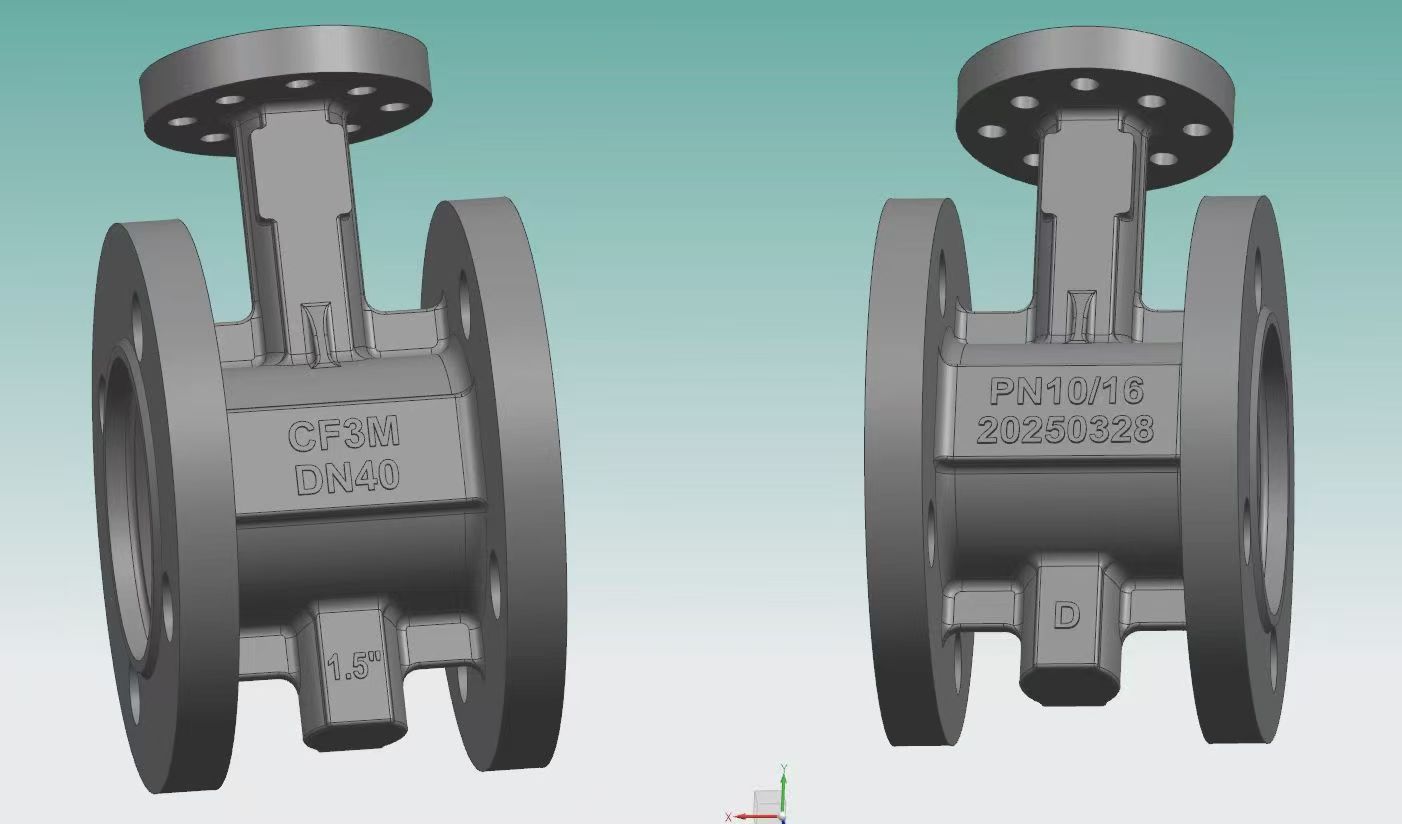

1. Valve Body Design

Connection Method:

The valve body is equipped with flanges at both ends, which connect directly to the pipe flange via bolts. This provides a reliable seal and easy installation, making it particularly suitable for high-pressure, large-diameter applications.

Material and Craftsmanship:

It is typically manufactured using casting or forging processes, ensuring the valve body possesses sufficient strength and rigidity to withstand the pressure of the medium in the pipeline.

Flow Optimization:

The smooth internal cavity design reduces fluid resistance and vortex flow, improving the valve's flow capacity and reducing energy consumption.

2. Butterfly Disc Structure

Core Component:

The butterfly disc is a circular or elliptical disc that controls the flow of the medium by rotating around its axis (0° to 90°).

Material Selection:

Depending on the medium characteristics, materials such as stainless steel, copper, nylon, rubber coating, or polytetrafluoroethylene (PTFE) can be selected to suit different operating conditions.

Eccentric Design:

Double eccentric structure: The valve stem axis is offset from the centerline of the butterfly disc, improving opening and closing torque, reducing friction, and extending service life.

Triple eccentric structure: This high-end design completely eliminates friction and is suitable for extreme operating conditions such as ultra-high temperatures and high pressures. 3. Sealing System

Sealing Type:

Soft Seal

Using elastic materials such as nitrile rubber and EPDM, it offers excellent sealing performance, but has limited temperature resistance (≤65°C).

Hard Seal

The valve seat and disc sealing surfaces are welded with stainless steel or cobalt-based carbide, offering high-temperature and high-pressure resistance and long service life.

Composite Seal

Soft and hard laminated metal sheets (such as a composite of flexible graphite sheets and stainless steel sheets) combine the advantages of both metal and elastic seals.

Sealing Characteristics:

No sliding friction between the disc and the sealing ring, reducing wear and improving sealing reliability.

The three-dimensional eccentric structure achieves a "tighter-closer" seal, suitable for high-pressure operating conditions.

4. Valve Stem and Actuator

The valve stem:

Connects the disc to the operating mechanism (manual, electric, or pneumatic) and must meet corrosion resistance and strength requirements.

Actuation Method:

Manual

Using a handle or gear drive, it is low-cost and suitable for small diameters and infrequent operation. Electric/Pneumatic

Equipped with a motor, reduction gear, or pneumatic piston, it enables remote control and automated adjustment, offering fast response and suitability for flammable and explosive environments.

5. Other Structural Advantages

Lightweight Design:

Compact overall size and light weight (only 1/3 to 1/2 that of a ball valve) save installation space.

Corrosion Resistance:

Corrosion-resistant materials such as 316L stainless steel and Hastelloy can be selected based on the media characteristics to extend service life.

Easy Maintenance:

Replaceable seals enable zero leakage after over 50,000 cycles of pressure-controlled opening and closing, reducing maintenance costs.