I. Industry Characteristics

High-Pressure and Low-Temperature Operating Conditions

Oil and gas pipeline pressures can reach Class 900 and above, and liquefied natural gas (LNG) temperatures can drop to -196°C. High-pressure and low-temperature-resistant valves (such as fully welded ball valves and low-temperature carbon steel ball valves) are required.

High differential pressures can easily lead to valve erosion, requiring optimized flow path design.

Corrosive Media

Natural gas contains corrosive components such as hydrogen sulfide (H₂S) and carbon dioxide (CO₂). Valves with seals made of stainless steel (316L), Hastelloy alloy, or fluoroplastic (PTFE) are required.

Long-term exposure to sulfur-containing environments accelerates the aging of valve seals.

Flammability and Explosion Risks

Natural gas leaks can cause explosions. Valves must have a fireproof design (API 607 certification) and explosion-proof actuators (Ex d certification).

Large Diameter and Long-Distance Transportation

Trunk pipelines often use large-diameter valves above DN500, requiring a balanced approach to flow control and sealing.

Intelligent and digital requirements

Integrated sensors are required for remote monitoring (such as flow, pressure, and temperature) and support for AI-powered predictive maintenance.

II. Valve Selection Considerations

Type Selection

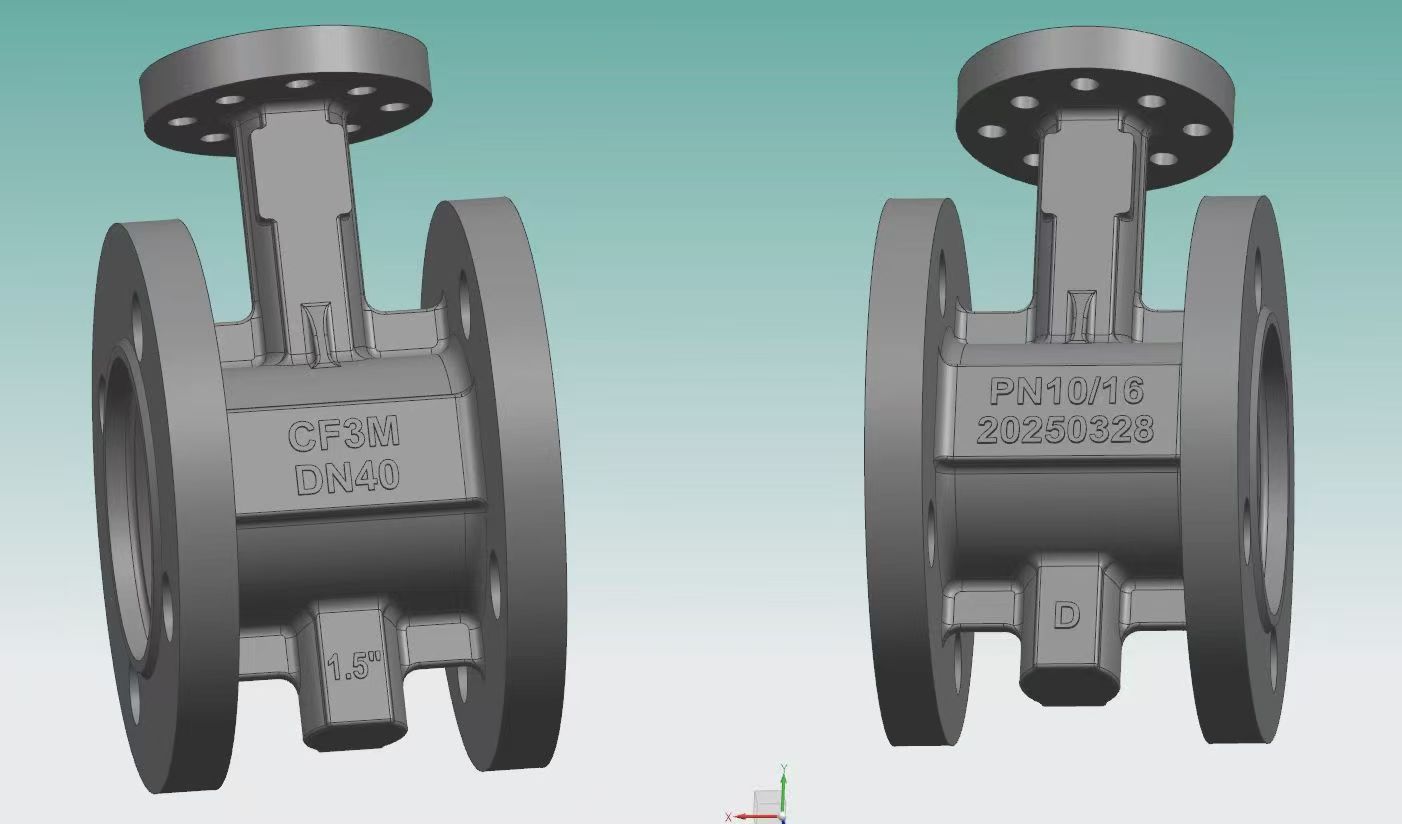

For high-pressure oil and gas pipelines: Metal-sealed ball valves or wedge-type gate valves with a pressure rating of ≥ Class 900 are preferred.

For sour natural gas: Use stainless steel with anti-corrosion coating, preferably API 6A certified valves.

For low-temperature applications: For LNG transportation, use low-temperature carbon steel (LCB) or austenitic stainless steel ball valves.

For flow control: Prefer V-shaped ball valves or butterfly valves to avoid erosion caused by gate valve throttling.

Material Compatibility: For corrosive media: Use 316L stainless steel for the valve body, and PTFE or graphite + 316SS for the sealing surfaces.

For high-temperature and high-pressure applications: Use forged steel valves (such as WC6 and WC9) with pressure ratings matching Class 600 and above.

Sealing Performance: Internal leakage ≤ GB/T 13927 standard, with zero tolerance for external leakage. Use double-disc or metal seals in key locations. For media containing particles, use a filter or knife gate valve to prevent seat wear.

Safety and Compliance: Fireproof design must be API 607 certified. For explosion-proof environments, use an explosion-proof actuator (Ex d).

Compliant with API 6D and ASME B16.34 and other international standards

Maintenance and Economy

For frequent operations, choose pneumatic/electric actuators to reduce manual intervention. For large-diameter pipelines, prioritize butterfly valves to reduce costs; for small-diameter pipelines, choose globe valves for their balanced performance. Regularly inspect and remove sediment and check seal wear.